Written by Gwen Hoheisel, Regional Extension Specialist, Washington State University, March 2020

One of the most sustainable practices conducted in the orchard is to maintain and operate your sprayer properly. The environmental and social repercussions from off-target drift are numerous and well documented. Economically, one of the largest preharvest costs is use and application of crop protection products and plant growth regulators. Poor timing of applications and poor operation of sprayers leads to poor pest management and an increase of culls. Investing a small amount of labor and supplies to conduct proper maintenance and optimization could reap great economic returns (https://treefruit.wsu.edu/article/the-deposition-triangle/). There are many different sprayer designs, but focusing on these two factors are universal priorities for all sprayers: proper maintenance of machine parts and matching air volume and direction with canopy shape.

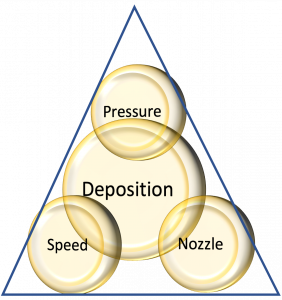

If you don’t already have one, create an annual checklist that can be used to inspect all hoses, pumps, bolts, and other machinery parts. In particular, the nozzles, pressure gauge, and speed directly affect the amount of deposition. If any of them change, deposition will also change (Fig. 1).

In an orchard system, nozzles should be changed at least annually if using ceramic and more frequently if using other metals. Pressure gauges should also be replaced annually and especially if the needle doesn’t return to zero or bounces frequently or the numbers are difficult to read (https://treefruit.wsu.edu/article/under-pressure-pressure-gauge-practices-for-sprayers/).

Improper setting of pressure has a direct effect on how much product (gallons per minute) comes from each nozzle as well as droplet size. An inexpensive $20 item can solve this problem.

Speed should be checked manually (methods found in this article https://treefruit.wsu.edu/web-article/six-steps-to-calibrate-and-optimize-airblast-sprayers/) and conducted annually especially if the sprayer has a rate controller. Making sure the rate controller speed matches the actual speed Is critically important to ensuring the correct gallons per acre. Speed sensors are either wheel base or GPS, both with their own disadvantages and advantages. Regardless, the computer of the rate controller must match the actual speed in order to ensure proper functioning.

Matching air volume and direction to the canopy architecture is the single greatest adjustment of the sprayer that would optimize spray deposition in the canopy. Manufacturers know this and have built numerous sprayer designs to take advantage of this. Basically, wherever air goes, spray goes. Therefore, if the air blows through two rows of trees, the spray will also drift that far. Reducing the air volume to keep it within one row means most of the spray will also stay in one row. As canopies become narrower and less dense, very little air is needed to propel the droplets into the canopy and rustle leaves. Some sprayers have fans that can be adjusted to spin slower and therefore decrease the air volume, while others have smaller fan blades to accomplish the same effect.

To maximize every drop to the crop:

- Invest in the time for maintenance checks and the minimal cost of new parts as it is far less expensive than applying the wrong rates of products leading to either too many chemicals used or poor control and more culled fruit.

- Invest in the labor for one person to optimize air volume and direction for each different canopy architecture on your farm. Test and adjust the sprayer settings early season and full canopy. Record the settings so that they can be used in all blocks with similar architecture.

Contact

Gwen Hoheisel

Gwen Hoheisel

Benton County Director

Regional Extension Specialist

Washington State University

ghoheisel@wsu.edu

treefruit.wsu.edu articles may only be republished with prior author permission © Washington State University. Reprint articles with permission must include: Originally published by Washington State Tree Fruit Extension at treefruit.wsu.edu and a link to the original article.