Authors: Ines Hanrahan and Felix Schuhmann, Washington Tree Fruit Research Commission

Conclusions at a Glance

- WA 38 develops two predominant starch patterns, which appear in a 6:4 ratio.

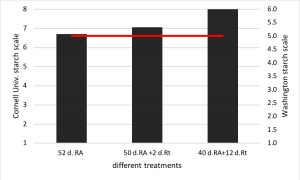

- WA 38 converts starch very slowly, thus providing a long harvest window.

- The reaction time for the iodine solution is significantly longer compared to other industry-specific varieties.

Introduction

During fruit growth, sugars produced via photosynthesis in the leaves of apple trees are stored as starch in developing fruitlets. With the onset of the maturation process of the apple fruit, the starch is slowly converted back to sugar. This process is visualized when using the iodine starch test as a maturity indicator. The method was probably discovered over 200 years ago, but the chemical structure of the starch-iodine complex, that causes the dark color, has remained undiscovered until 2016 (Madhu et al., 2016). Each apple variety has a unique starch staining pattern and the speed of disappearance of the staining during fruit ripening varies. Around the world, each growing region has adopted their own specific starch scale. For example, most of the growers on the East Coast of the US use a 1-8 scale (aka Cornell starch scale), German growers utilize a 1-10 scale, and apple producers in South Tyrol rely on a 1-5 chart. In Washington, a 1-6 scale is typically used. All scales have in common, the percentage of staining is gaged for two regions of the fruit: the core and the flesh area. In addition, variety specific starch scales have been available to Washington growers. The new cv. WA 38 of the Washington State University breeding program is a fast-emerging variety. In fact, 40% of new plantings in the State of Washington in 2018 will be cv. WA 38 (Neal Manly, 2017). With the first harvest approaching in 2019, there is the need for an advanced, variety specific starch scale.

2018 Experimental Design

WA 38 apples were picked in four different locations (WSU Prosser (Roza), Prosser, Quincy, WSU Sunrise orchard). Sample fruit were picked in the orchard before the actual harvest from 10/09 – 10/12/2017. After harvest, additional fruit samples were stored at 33°F. In mid-November, a sample of 40 fruit was stored at room temperature, to advance maturity. Apples were cut, stained, and pictures were taken between 9/25/2017 and 11/29/2017.

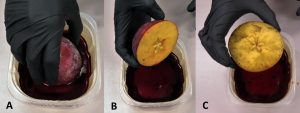

To prepare the apples:

- The apples were cut in half through the equator.

- The freshly cut apple surface was dipped in iodine solution to fully cover the fruit flesh (Figure 1 A-C).

- After 30 mins the pattern was fully developed and the surface was then dried with a paper towel.

- A picture was taken under consistent light environment (i.e. a photo box).

- The pictures were evaluated and grouped.

For the new starch scale, 638 apple samples were cut; 81 in September, 371 in October and 186 in November.

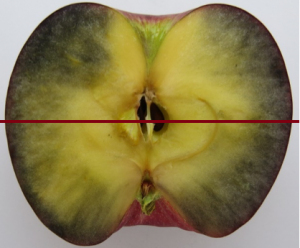

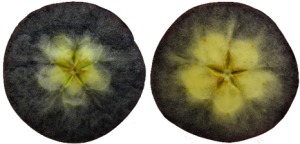

To achieve a surface reflecting the middle of the core, WA 38 apples were cut, unlike other industry-specific varieties, right through the equator (Figure 2). During the experiment, two predominant patterns were observed. The commonly known “flower” pattern (Figure 3), which is characterized by five “flower petals” growing with advancing maturity. The other pattern was named “radial” (see Figure 4) and can be compared with a “sun rise”. It clears larger parts of the cut surface in a radial fashion with advanced maturity. The patterns appeared in a 6:4 ratio, respectively.

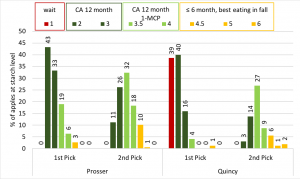

Another observation was the slow disappearance of dark color (aka slow fruit ripening) both on the tree and in storage (Figure 6). This was similar to observations from previous years with cv. WA 38 apples at the WTFRC (Figure 5). In the new starch scale this fact was considered and a scale with half point increments was developed.

2017 seasonal observations also showed that the starch patterns took longer to develop, compared to other industry-specific varieties. Depending on fruit temperature and maturity, the development of a complete starch staining took up to one hour. In most cases, the pattern developed fully after 30 minutes. If the fruit flesh temperature roughly equals room temperature(±72°F), starch readings are possible in less than 5 minutes. However, since this variety may be picked in late September or early October, fruit flesh temperatures in the field may be considerably lower, especially when attempting to stain fruit in the morning.

We have used an industry focus group (fieldmen, QC personnel, R&D personnel, scientists) to gather feedback on various stages of the actual starch scale and on potential best layout options. Based on input received, we plan on providing two chart options to growers: a) a detailed two-page description of the starch patterns with and without half steps, b) a 6×8 inch card showing half steps (0.5 increments) following the exact layout of other available starch pattern cards for Washington grown apple varieties.

Future Plans

We will incorporate feedback received from our industry focus group and any additional comments. The scale will then be refined in 2018 by incorporating:

- Additional pictures of missing starch staining steps;

- The exact time and conditions needed for accurate starch readings;

- A comparison of starch movement on and off the tree;

- A vertical starch pattern to predict the likelihood of splits in the stem bowl.

If you would like to participate in the industry focus group or would like to review current draft versions of the starch scale, please contact Ines Hanrahan.

Suggested additional reading

Good Fruit Grower, Vol. 69, NO. 3. Slicing into Cosmic Crisp (Article by Shannon Dininny). page 44-47.

Literature cited

Madhu, S., Evans, H.A., Doan-Nguyen, V.V., Labram, J.G., Wu G., Chabinyc, M.L., Seshadri, R., Wudl, F. (2016) Infinite Polyiodide Chains in the Pyrroloperylene–Iodine Complex: Insights into the Starch–Iodine and Perylene–Iodine Complexes. Angewandte Chemie Int. Ed. 55(28): 8032-5.

Manly, N. (2017). Out of this World Expectations for ‘Cosmic Crisp’ Apple. Growing Produce (Article by Christina Herrick) http://www.growingproduce.com/fruits/apples-pears/out-of-this-world-expectations-for-cosmic-crisp/

Contact

Ines Hanrahan

Ines Hanrahan

Washington Tree Fruit Research Commission

hanrahan@treefruitresearch.com