Tianna DuPont, Washington State University Extension; Mark Mazzola, USDA-ARS; Shashika Hewavitharana, California Polytechnic University. January 26, 2021.

Download PDF

When apple replant disease occurs, it can cost orchardists $70,000 to $150,000 in reduced returns during just the first four years of production. Washington growers generally fumigate using 1-3 Dichloroproprene, Chloropicrin to try to prevent the complex of pathogens which cause replant. But fumigation generally only provides short term benefits. Growers asked for alternatives that may provide longer term benefits and higher returns allowing them to maintain their organic status.

Current study

In 2017 we initiated three studies looking at anaerobic soil disinfestation and bio-renovation using Brassica seed meal treatments that have worked well at a small scale and in field applications in strawberries. To see if these treatments are ready for field application, we used large field plots of one to twelve-acres where we could look at variability across a field and use field scale equipment. Studies were conducted in three locations with 4 to 5 replications.

Bio-renovation using mustard seed meals releases volatile compounds produced by the interaction between the mustard plant compound glucosinolate with a plant enzyme (myrosinase). Volatiles suppress soil-borne disease organisms and can select for beneficial microorganisms that directly parasitize plant pathogens and induce plant defense. See Figure 1.

Anaerobic soil disinfestation (ASD) is a process where organic carbon sources are added to the soil and then the soil is flooded using irrigation and covered by a gas impermeable plastic film. During anaerobic decomposition, microbes release volatile compounds which are toxic to plant parasites and pathogens. See Figure 2.

A fumigated control (1,3-Dichloropropene, Chloropicrin) and a no-treatment control were included in each site.

We planted trees the spring following summer/fall soil treatments. Orchards were planted to cv WA 38 on G41 in Othello (spring 2018), cv TC2 on Bud 10 Rootstock in Tonasket and cv WA 38 on G41 and M9.337 in Rock Island (spring 2019).

Figure 1. Steps to Brassica seed meal bio-renovation.

Step 1. Apple Brassica seed meal when soils are warm.

Step 2. Incorporate mixing well.

Step 3. Totally impermeable film.

Step 4. Treatments for 3 weeks.

Leave TIF in place for 3 weeks.

Step 5. Aerate soil 3 weeks or more.

Remove TIF and allow soil to aerate. Volatile compounds from bio-renovation are phytotoxic. Bio-renovation was performed the fall before planting.

Figure 2. Methods for anaerobic soil disinfestation (AASD) employed at three field sites in WA.

Step 1. Carbon source from grass cover crop or hay 8 to 10 ton per acre.

New Findings

Did treatments change the soil biology?

Bio-renovation treatments can initiate successive changes to the soil microbiome. For example, during ASD when the soil goes anaerobic bacterial communities generally progress from dominance by Bacillus and Paenibacilus groups to dominance by anaerobic bacteria including Clostridium. Clostridium produce a variety of chemistries such as volatile fatty acids which inhibit fungi and dimethyl disulfide which is nematocidal and fungicidal. Volatile compounds reduce the numbers of pathogens in the soil and ideally the shift in the soil microbiome is more stable than that observed in response to fumigation where communities often quickly revert to high parasite/pathogen levels.

We measured the soil biology three weeks after soil treatments using Terminal restriction fragment length polymorphism (T-RFLP) analysis. The soil bacterial and fungal communities in the Brassica seed meal treatment were different than the no-treatment control and the fumigated control in all three sites. In the anaerobic soil disinfestation treatment bacterial and fungal populations were different than in the no-treatment control in Rock Island and Tonasket but not in Othello. Lack of soil biology transformation in Othello ASD treatments was likely because those soils did not stay wet enough to become anaerobic when we used sprinkler irrigation. When treatments were performed again in Othello using drip vs sprinkler irrigation application microbial communities did shift in ASD. We looked at microbial communities again the fall after trees were planted using high-throughput DNA sequencing of soil in the root rhizosphere (Figure 3). A year after treatment bacterial communities were still different in Brassica seed meal treated soil compared to non-treated soil in Tonasket and Rock Island as well as two years later in Othello.

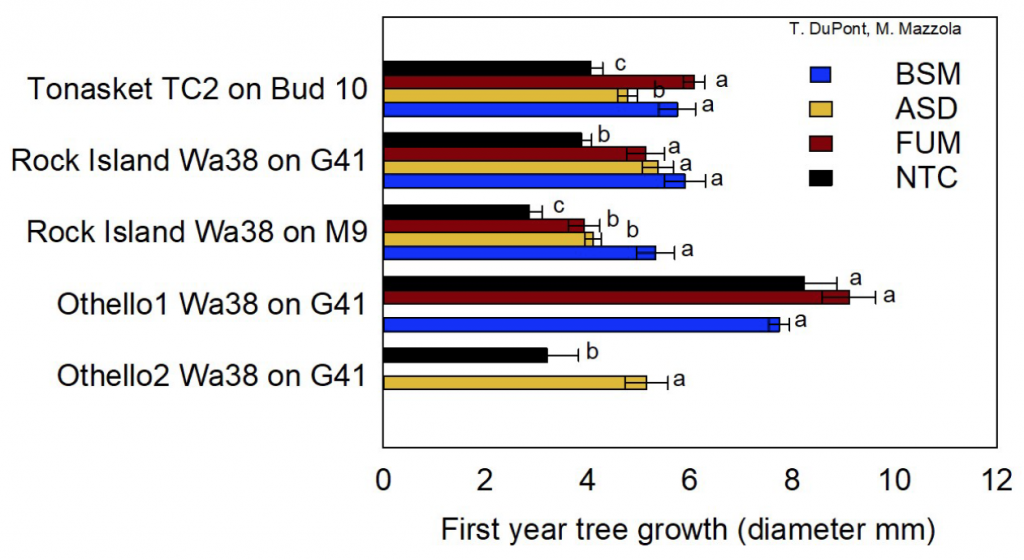

Impacts on tree growth

Cost-benefit over the first five years will tell us whether treatments were successful. To give you a sneak peek let’s look at initial tree growth. Tree growth in Brassica seed meal treatments was greater than or equal to tree growth in fumigated plots at all sites during first year growth as well as in second year growth in Othello (Figure 5). The anaerobic soil disinfestation treatment was more variable. In Tonasket, anaerobic soil disinfestation tree growth was greater than the no-treatment control but less than the fumigated control. In Rock Island anaerobic soil disinfestation tree growth on M.9 and G.41was as good as the fumigated control and greater than the no-treatment control. In Othello, the anaerobic treatment was fumigated in order to avoid risking four acres of grower trees after anaerobicity was not achieved and thus impacts are not reported here.

Tips for Growers

Brassica seed meal bio-renovation is looking promising as an alternative to fumigating with 1,3-Dichloropropene, Chloropicrin. If you are considering this option keep in mind that not all brassica seed meals are equal. The seed meal used here was a 1:1 formulation of B. juncea and S. alba (Mazzola 2015). Seed meals are often processed at different temperatures and with different grinding methods which affect the quantity of active chemistry that is released. Tests should be conducted to determine the type and quantity of glucosinolate contained in the seed meal that you intend to use. To date in the US, the Brassica seed meal we used is labeled only as a fertilizer. Until products have the appropriate labels as a soil fungicide/nematicide, application for this use is not legal. Remember that soil temperature and moisture are important. These are biological processes where moisture and temperature affect the activity of soil biology and the movement through the soil of the compounds they produce. For Brassica seed meal, treatment soil should be warm (above 70° C) and moist. Last, application rate is important.

Anaerobic soil disinfestation resulted in significant changes in composition of the rhizosphere microbiome and tree growth that was better than the no-treatment control in three of four experiments but not always greater than the fumigated control. It will be essential to keep soil wet (above 30% moisture) and reach anaerobic conditions for success. In sites with high pratylenchus nematode populations, higher carbon inputs and longer incubation times might be necessary for success.

Next steps

We plan to follow these plots for at least three more seasons to have five years of tree growth and three years of harvest data. Returns from packed fruit over the long-term compared to costs will let us track success. Additional work is also needed to further improve the practical application of treatments.

For further information

DuPont, S. T, Hewavitharana, S.S., Mazzola, M. Field scale application of Brassica seed meal and anaerobic soil disinfestation for the control of replant disease. Applied Soil Ecology (submitted Sept 2020).

Wang, L., and Mazzola, M. 2019. Field evaluation of reduced rate Brassicaceae seed meal amendment and rootstock genotype on the microbiome and control of apple replant disease. Phytopathology 109:1378-1391.

Mazzola, M., Hewavitharana, S. and Strauss, S. L. 2015. Brassica seed meal soil amendments transform the rhizosphere microbiome and improve apple production through resistance to pathogen re-infestation. Phytopathology 105:460-469.

Mazzola, M., Muramoto, J., Shennan, C., 2018. Anaerobic disinfestation induced changes to the soil microbiome, disease incidence and strawberry fruit yields in California field trials. Appl. Soil Ecol. 127, 74-86.

Hewavitharana, S.S., Mazzola, M., 2016. Carbon source dependent effects of anaerobic soil disinfestation on soil microbiome suppression of Rhizoctonia solani AG-5 and Pratylenchus penetrans. Phytopathology 106, 1015–1028.

Hewavitharana, S.S., Reed, A.J., Leisso, R., Poirier, B., Honaas, L., Rudell, D.R., Mazzola, M., 2019. Temporal dynamics of the soil metabolome and microbiome during simulated anaerobic soil disinfestation. Front. Microbiol. 10, 2365.

Funding Sources & Acknowledgements

This project was supported by grants from the Washington State Tree Fruit Research Commission grant # 10211000 and the USDA Crop Protection grant # 2017-70006-27267. Thank you to in-kind support from Progen Seed, Trident Ag Products, Farm Fuel Inc and generous support of labor, materials, and equipment from orchardists Mike Robinson, Jim Baird, and Sam Godwin.

Appendix

Table 1. Field Operations Othello, WA

| Anaerobic soil disinfestation application | |||

| Operation | Implement/Equipment | Details | Date |

| Fertilize | April 2017 | ||

| Tillage | John Deere 7200/ 15 ft disc | April 2017 | |

| Seed triticale | John Deere 7200/ Great Plains seed drill | 95 lbs per acre | April 19, 2017 |

| Irrigation | Hand lines (R33 sprinklers) | 6 gal per min, 0.26 inch per hr | May-June 2017 |

| Cut and swath | John Deere 7200 R450/ swather | 4 ft windrow | June 28 2017 |

| Chop | Pak flail | 0.7 mph | July 3, 2017 |

| Incorporation | John Deere 7200/ Celli rototiller | 8 inch depth | July 4, 2017 |

| Tarping | Kubota M8540/ Mulch layer Mechanical Transplanter Co Model 90 | July 7, 2017 | |

| Brassica seed meal application | |||

| Operation | Implement/Equipment | Details | Date |

| Pre-irrigation | Hand lines (R33 sprinklers) | 6 gal per min, 0.26 in per hr | July 15, 2017 |

| Mustard meal application | John Deere 5083/ Whatcom mulch spreader | Settings: 4 low, 1700 rpm, belt 5, floor 4, gate 12.5 inch | July 19, 2017 |

| Incorporation | John Deere 7200/ Celli rototiller | 8 inch depth | July 19, 2017 |

| Tarping | Kubota M8540/ Mulch layer Mechanical Transplanter Co Model 90 | N/A | July 19, 2017 |

Table 2. Filed Operations Rock Island, WA

| Anaerobic soil disinfestation application | |||

| Operation | Implement/Equipment | Details | Date |

| Pre-Irrigation | Sprinkler system (R5 sprinklers)/ Big gun system (8mm nozzle) | 1.5 acre-inch applied | July 2-4, 2018 |

| Hay distribution | By hand | 8 ton per acre | July 4, 2018 |

| Hay chopping | Falail mower | July 4, 2018 | |

| Incorporation | Mascchio Rototiller | 8 inch depth | July 5, 2018 |

| Tarping | Mechanical Transplanter | N/A | July 5, 2018 |

| Saturation | Drip irrigation to flood soil | 0.44 acre-inches per hr | July 6-27, 2018 |

| Brassica seed meal application | |||

| Operation | Implement/Equipment | Details | Date |

| Mustard meal application | Whatcom compost spreader 750 | Settings: 2 floor, 2 belt | July 6, 2018 |

| Incorporation | Mascchio Rototiller | 8 inch depth | July 6, 2018 |

| Tarping | Mulch layer Mechanical Transplanter Co Model 90 | Within 20 min of mustard incorporation | July 6, 2018 |

Table 3. Field Operations Tonasket, WA

| Anaerobic soil disinfestation application | |||

| Operation | Implement/Equipment | Details | Date |

| Pre-Irrigation | Big gun system (8mm nozzle) | 5 acre-inch applied in 12 hr sets | Aug 2-6, 2018 |

| Hay distribution | By hand | 8 ton per acre | Aug 8, 2018 |

| Hay chopping | Falail mower | Aug 8, 2018 | |

| Incorporation | Mascchio Rototiller | 8 inch depth | Aug 8, 2018 |

| Tarping | Mulch layer Mechanical Transplanter Co Model 90 | N/A | Aug 8, 2018 |

| Saturation | Drip irrigation to flood soil | 0.44 acre-inches per hr | Aug 8-29, 2018 |

| Brassica seed meal application | |||

| Operation | Implement/Equipment | Details | Date |

| Mustard meal application | Mill Creek mulch spreader | 1.7 lbs per tree row ft Settings: 4 floor, 4 belt |

Aug 9, 2018 |

| Incorporation | Mascchio Rototiller | 8 inch depth | Aug 9, 2018 |

| Tarping | Mulch layer Mechanical Transplanter Co Model 90 | Within 20 min of mustard incorporation | Aug 9, 2018 |

Table 4. Treatment Costs

| Anaerobic Soil Disinfestation (ASD) – Carbon grown in place. | ||||

| Field Activity | hrs/A | $/hr | $/A | |

| Tillage | 0.25 | $40 | $10 | |

| move irrigation triticale | 4.0 | $13 | $52 | |

| seeding triticale | 0.25 | $40 | $10 | |

| cut and swath triticale | custom | $50 | ||

| flail | 1 | $40 | $40 | |

| hay rake | custom | $7 | ||

| hand rake | 2.8 | $13 | $36 | |

| move irrigation for ASD | 4.0 | $13 | $52 | |

| lay plastic | 2.0 | $40 | $80 | |

| Supplies | $/unit | unit | unit/A | $/A |

| triticale seed | 0.32 | lb | 100 | $32 |

| Totally impermeable film | 0.06 | ft | 4200 | $252 |

| Equipment | equip | yrs amortized | A/yr | $/A |

| hand lines | $650 | 10 | 50 | $1.30 |

| flail | $4,000 | 10 | 50 | $8 |

| plastic layer | $2.300 | 10 | 50 | $5 |

| seed drill | ||||

| Total cost | $635 | |||

| Anaerobic Soil Disinfestation (ASD) – Hay carbon source | ||||

| Field Activity | hrs/A | $/hr | $/A | |

| pre-irrigate | 3 | $14 | $41 | |

| apple hay | 16 | $14 | $213 | |

| flail hay to chop | 1 | $40 | $40 | |

| place drip lines | 5.25 | $14 | $71 | |

| lay plastic | 2 | $40 | $80 | |

| Supplies | $/unit | unit | unit/A | $/A |

| hay | $100 | ton | 8 | $800 |

| hay shipping | $500 | ea | 1 | $500 |

| drip line | $0.07 | ft | 8400 | $546 |

| drip couplings | $3.63 | ea | 20 | $73 |

| Totally impermeable film | $0.06 | ft | 4200 | $267 |

| Equipment | equip | yrs amortized | A/yr | $/A |

| flail | $4,000 | 10 | 50 | $8 |

| plastic layer | $2,300 | 10 | 50 | $5 |

| Total cost | $2,642 | |||

| Brassica seed meal bio-renovation | ||||

| Field Activity | hrs/A | $/hr | $/A | |

| irrigation | 4 | $13 | $52 | |

| mustard meal application | 2 | $13 | 426 | |

| incorporation | 2 | $13 | $26 | |

| tarping | 2 | $13 | $26 | |

| Supplies | $/unit | unit | unit/A | $/A |

| mustard meal* | $0.85 | lb | 6720 | $5,712 |

| Totally impermeable film | $0.06 | ft | 4200 | $267 |

| Equipment | equip | yrs amortized | A/yr | $/A |

| mulch spreader | $22,000 | 10 | 100 | $22 |

| plastic layer | $2,300 | 10 | 50 | $5 |

| Total cost | $6,135 | |||

| Fumigation | ||||

| Field Activity | hrs/A | $/hr | $/A | |

| Total cost | custom | $900 | ||

*1.6 lbs per tree-row-foot for 4 foot wide tree strips.

Contact

WSU Extension Specialist, Tree Fruit

tianna.dupont@wsu.edu

(509) 663-8181 ext 211

Treefruit.wsu.edu articles may only be republished with prior author permission © Washington State University. Republished articles with permission must include: “Originally published by Washington State Tree Fruit Extension Fruit Matters at treefruit.wsu.edu” along with author(s) name, and a link to the original article.