By Ines Hanrahan (Washington Tree Fruit Research Commission, WTFRC), and Rob Blakey (Washington State University, WSU)

At a Glance

- Storage success ALWAYS starts in the orchard; monitor: orchard history, crop load, and fruit maturity to minimize fruit disposition to disorder development.

- Honeycrisp storage considerations involve three groups of physiological disorders:

- Chilling injury

- Bitter pit

- Carbon dioxide (CO2) injury.

- Continue with conditioning at 50°F for 7 days, final temperature of 37-39°F, O2 of 2-4% and CO2 of 0.5-1.0%.

- Stack bins for good airflow and monitor the CO2 concentration as soon as fruit are loaded into a room.

- Actively scrub CO2 and use lime.

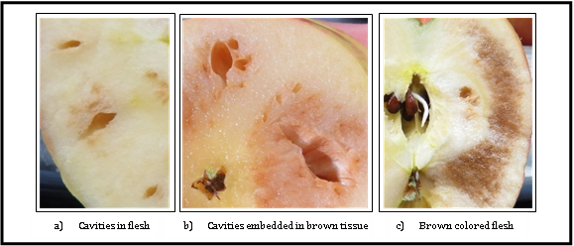

Storing Honeycrisp long-term while achieving good packouts and maintaining fruit of acceptable eating quality in the second part of the storage season has been a continuous challenge for our industry. However, up until last year most packers had become comfortable knowing what types of performance to expect out of each lot. With Honeycrisp you basically had to control your decay, manage chilling injuries (mainly soft scald), and bitter pit. We did know that this apple was sensitive to carbon dioxide injury, but aside from the occasional cavities (Figure 1), most packers did not report having significant problems.

In 2016, Honeycrisp revealed another set of postharvest issues, namely carbon dioxide injury (CO2). The prime reason for the development of this disorder during fruit storage is a CO2 concentration that is higher than the tissue can tolerate. CO2 injury in apples is one of the postharvest disorders that can be notable after storage as an internal or external disorder. During the 2016-2017 storage season, packers reported fruit with symptoms starting in March, but in controlled experiments, symptoms developed and become discernible during the first 4 months of CA storage (Mattheis, 2012). In Honeycrisp, we have noted a clear separation between fruit displaying internal versus external symptoms (Figure 1 & 2; Hanrahan et al., 2017). Fruit that exhibits external symptoms does not usually present internal symptoms. Once expressed, symptoms do not worsen at room temperature, but lesions may become infected with decay fungi, rendering some areas to appear almost black, depending on the pathogen (Figure 2).

The susceptibility to injury caused by CO2 can be influenced by many different preharvest factors including fruit maturity at harvest, seasonal weather conditions, and crop load. Mature fruit tend to display more flesh browning, while immature fruit are more susceptible to skin injury (Mattheis, 2012). In general, fruit grown in colder regions or higher altitude are more susceptible to CO2 injury (Elgar et al. 1999). However, several preharvest factors are usually interacting to determine the final fruit sensitivity and cultivar-specific aberrations. For instance, the likelihood of Braeburn to show flesh browning and cavities seems to be higher in trees with low crop load and late harvested fruit (Elgar et al. 1998).

If the CO2 concentration in the storage room is properly managed, fruit may never develop visible injury in CA storage, even if an individual lot sensitivity to CO2 injury is deemed high. There are major variables influencing symptom initiation during the postharvest period, including the duration and rate of fruit cooling (Beaudry et al., 2014). It has been reported that specific cultivars tend to develop more external symptoms at higher storage temperatures, while low storage temperatures increase the amount of internal flesh browning (Watkins and Liu, 2010). 1-Methylcyclopropene (1-MCP) has also been shown to increase the susceptibility to CO2 injury in several cultivars (Mattheis, 2012; DeEll et al., 2003).

Current storage recommendations for Honeycrisp

Storage success ALWAYS starts in the orchard so it is essential to work closely with field staff. Specifically, knowledge of orchard history, crop load, tree age, and fruit maturity will give clues about what type of disorder/s the particular lot may be sensitive to. Maturity management in Honeycrisp remains the most important factor when attempting to store fruit, and is complicated by a tight labor supply. Both early and late harvest will affect the sensitivity of the fruit to disorder development. Early harvest will increase bitter pit in storage, and external CO2 injury, while late harvest will increase the chance for pre- and postharvest chilling injury (soft scald and soggy breakdown), internal CO2 injury, and decay in storage. Crop load must be managed because fruit will ripen ‘normally’ only when crop load is managed correctly. Low crop load will lead to big fruit with bitter pit, while high crop load will cause fruit to never ripen properly, have premature starch clearance, never develop typical flavor and show a delay in red color development.

Based on work done by Jim Mattheis (USDA-ARS, Wenatchee) and Ines Hanrahan (WTFRC, Yakima) the following can minimize the expression of chilling injury (soft scald, soggy breakdown) in Honeycrisp apples. Harvest fruit with breaking ground color, starch clearance to 4.5-5.0 (1-6 Honeycrisp starch scale – link below). Fruit intended for long-term storage should be segregated by titratable acidity (≥0.5 is best for long term storage). Fruit intended for long-term storage will also benefit from 1-MCP treatment (to maintain acidity, and reduce skin greasiness), but 1-MCP treatment can affect the sensitivity of fruit to CO2 injury (DeEll et al., 2016). Following harvest, fruit needs to be preconditioned for a minimum of 7 days at 50oF including the last fruit into a room. Do not shorten the temperature conditioning period.

The final storage temperature in CA should be between 37-39oF. To achieve this, one can consider a fast or a slow pulldown. Fast pulldown equals an active pulldown of temperatures as fast as possible. This can lead to a high differential between coil temperature and room temperature, which in turn may dehydrate the fruit but can reduce the development of bitter pit. Most often, a slow pulldown would be adequate. That means temperatures are lowered by 1-2oF every other day. An intermediate approach to temperature pull down may be to watch the coil temperature and the room temperature and keep both as close to each other as possible.

Final oxygen levels should be kept at 2-4% and carbon dioxide levels at 0.5-1%. For lots with bitter pit as a major concern, CA can be initiated during the preconditioning period to decrease the incidence of bitter pit in storage without having a negative impact on chilling disorders.

For additional reading, please refer to a final report submitted to the WTFRC by Mattheis, Hanrahan & Rudell (tinyurl.com/HCstorage)

Considerations to manage CO2 injury in Honeycrisp

Most varieties cited for being sensitive to this disorder in the literature do not have the added problem of chilling sensitivity. However, the likelihood of CO2 injury symptom expression depends mostly on cultivar and maturity of the fruit. Most recommendations for Honeycrisp have been developed in Michigan or the eastern part of North America.

CAUTION: Please keep in mind that these results may not translate to our conditions and have not been proven in our region yet.

- The concentration of CO2 and oxygen should be monitored and managed once fruit are moved into a room, even if fruit are not in CA.

- Delayed CA establishment of 4 weeks can significantly reduce the appearance of internal CO2 related flesh browning (DeEll et al., 2016) – but can exacerbate bitter pit.

- Good airflow in the storage room should be established to prevent a partial rise in respiration activity in storage. For example, storage in cardboard boxes can cause a rise in CO2 concentration and thus cause severe CO2 injury (Watkins and Yahia, 2008). In general, good airflow in storage rooms can be achieved by following symmetrical pattern of tight-stacked bins (Hellickson, 2005).

- The application of diphenylamine (DPA), an antioxidant, may help to reduce the risk of internal and external CO2 injury (Mattheis, 2012). A study from Michigan State University demonstrated a reduction of CA-related CO2 injury in Honeycrisp apples with a pre-storage treatment of about 1,000 ppm DPA in combination with a preconditioning of 5 days at 10°C or 20°C to manage chilling injury (Beaudry et al., 2014). Please note, DPA is currently registered for superficial scald control and is NOT registered for use for CO2 injury. Always read the label before use, and consult with your DPA supplier if needed.

- Standard 1-MCP applications for 24 h have been shown to affect sensitivity of fruit to CO2. For example, DeEll et al. (2016) found 1-MCP treatment negated the positive effect of delayed CA in reducing internal CO2 injury in Honeycrisp.

Summary

Growing practices (cropload, tree age, etc.) and maturity interact to influence disorder predisposition and/or response of individual fruit lots to postharvest interventions. Hence, it is necessary to develop individualized methods for each orchard. Successful storage balances your specific needs and will require knowledge of your orchards.

Please contact us if you have problems with storing fruit.

Contact:

Ines Hanrahan: hanrahan@treefruitresearch.com

Ines Hanrahan: hanrahan@treefruitresearch.com

Rob Blakey: rob.blakey@wsu.edu

Additional resource:

https://treefruitresearch.com/resources-a-downloads/starch-iodine-index-for-honeycrisp

Acknowledgement: We would like to thank Jim Mattheis (USDA-ARS, Wenatchee) for critically reviewing this newsletter article.

Literature cited

Beaudry, R.M., Contreras, C. and Tran, D. (2014). Toward optimizing CA storage of Honeycrisp apples: Minimizing pre storage conditioning time and temperature. New York Fruit Quarterly Fall 2014, 9-14.

DeEll, J.R., Lum, G.B. and Ehsani-Moghaddam, B. (2016). Effects of delayed controlled atmosphere storage on disorder development in ‘Honeycrisp’ apples. Canadian Journal of Plant Science, 96 (4) 621-629.

DeEll, J.R., Murr, D.P., Wiley, L. and Porteus, M.D. (2003). 1-Methylcycloprpene (1-MCP) increases CO2 injury in apples. VIII International Controlled Atmosphere Research Conference. International Society for Horticultural Science 600 (37), 277-280.

Elgar, H.J., Burmeister, D.M. and Watkins, C.B. (1998). Storage and handling effects on a CO2– related internal browning disorder of ‘Braeburn’ apples. Hort Science 33 (4), 719-722.

Elgar, H.J., Watkins C.B. and Lallu, N. (1999). Harvest data and crop load effects on a carbon dioxide-related storage injury of ‘Braeburn’ apple. HortScience 34 (2), 305-309.

Hanrahan, I., Vorholz, M., DeEll, J. 2017. Identification and management of carbon dioxide injury in apples. Acta Hort. (submitted)

Hellickson, M. (2005). Improving air distribution in fruit storage warehouses. Paper presented at: Washington Tree Fruit Postharvest Conference. pp1-5 (Wenatchee, USA: WSU-TFREC Postharvest Information Network) www.postharvest.tfrec.wsu.edu.

Mattheis, J. (2012, Feb 15). Dealing with carbon dioxide sensitivity. The Good Fruit Grower (M. Hansen, Interviewer).

Watkins, C.B. and Yahia, E. (2008). Apples, controlled atmosphere storage. Retrieved from Global Cold Change Alliance: http://www.gcca.org

Watkins, C.B. and Liu F.W. (2010). Temperature and carbon dioxide interactions on quality of controlled atmosphere-stored ‘Empire’ apples. HortScience, 1708-1712.

Watkins, C.B., Nock, J.F. (2012). Controlled-atmosphere storage of ‘Honeycrisp’ apples. Hort Science, 886-892.