Written by Carolina Torres and Raquel Gomez, WSU TFREC, Wenatchee, May 2020.

Collaborators: Ines Hanrahan, Washington Tree Fruit Research Commission, Karen Lewis, WSU Extension Tree Fruit Specialist, and WA fruit packing companies.

Summary

WA 38, the newest cultivar developed and released by the Washington State University apple breeding program, was first introduced to the market in December of 2019. Growers and researchers are currently working together to create cultivar specific practices needed to maintain consistent product quality, ensure grower profits, and guarantee consumer satisfaction. Cullage analysis was done during commercial packing to determine defects responsible for culls with the end goal of developing good practices for the 2020/2021 season. WA 38 performed well in its first commercial packing season, with average packouts from second and third crop trees of 82%. Evaluation of the culls found mechanical-type damages, like stem punctures and limb rub to be predominant discards. Green Spot was also among the top ones, with a higher percentage in fruit from the third leaf trees. Fruit greasiness was a transversal issue that was observed, and for the most part, taken care of, by each packinghouse and their coating provider. In the future, proper adjustments to harvest maturity need to be taken into consideration to minimize this fruit condition. In order to further improve packouts in future seasons growers may consider stem clipping at harvest to avoid stem punctures and tree structure adjustment after discussing it with field advisors/Horticulturists.

Introduction

WA 38, the newest cultivar developed and released by the Washington State University apple breeding program, was first released to market in December of 2019. Producers, packers, and researchers are currently working together to create cultivar specific practices needed to maintain consistent product quality, ensure grower profits, and guarantee consumer satisfaction. As growers become more familiar with this variety, it becomes apparent, that as with any cultivar there are nuisances or maladies or challenges to address. Recent work has shown that green spot and stem punctures are of concern when working with this variety. Green spot is a potential disorder seen in WA 38. It refers to a spotted discoloration mostly seen on the shoulder of the fruit but can occur in the equatorial region of the fruit as well. Thus far the symptoms are seen mostly in the peel but may begin to impact the flesh as severity increases (Sallato and Bishop, 2019; view their article). Considering the recent commercial release, very little information is available regarding the cause and control of this anomaly, but researchers are considering nutritional imbalance as the cause. Stem punctures occur when a stem or spur, punctures the skin of an adjacent fruit, this can consequently increase the incidence of rot in fruit. Limb rub is present as a brown to dark brown spot on the skin which occurs from repeat rubbing on a limb which creates a scar and makes the fruit undesirable to consumers. Stem clipping has been shown to significantly decreased culls due to stem punctures as well as decay in prolonged storage (Hanrahan, 2018; View the stem puncture article). In this context, the objective of this study was to identify the common defects causing culls in commercially grown WA 38 and to provide information for educated decisions in the new growing season. These common defects can be seen in figure 1.

Methods

The cullage analysis was done on second and third crop trees. About 25,600 fruit or 16 bins of apples were analyzed with the means of quantifying the damages responsible for the cull. In the various packing houses visited (n=8), cull bins (juicer/process, peelers and slice) were selected and each fruit inspected, and defect identified. A random sample was collected from each bin to assess fruit maturity by measuring firmness (lbs), soluble solids (◦Brix), starch index (SI), titratable acidity (% malic acid), IAD, background color (1-4), % red coverage, and weight. The SI was assessed using the Cosmic Crisp® starch scale developed by the Washington Tree Fruit Research Commission.

Results and Discussion

Packouts and cull analysis

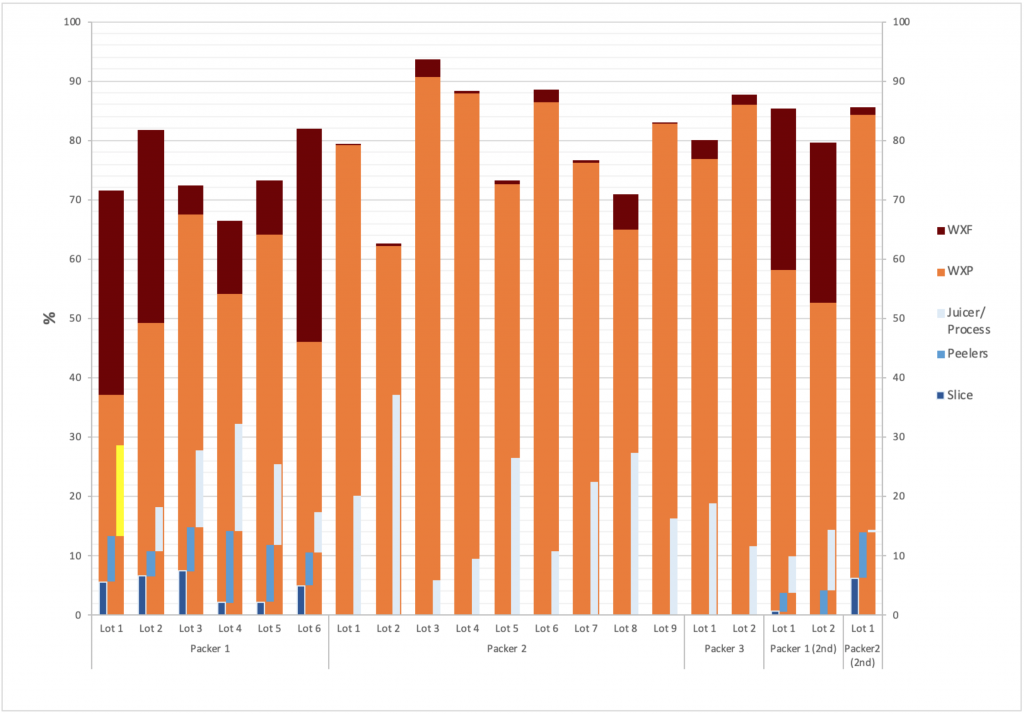

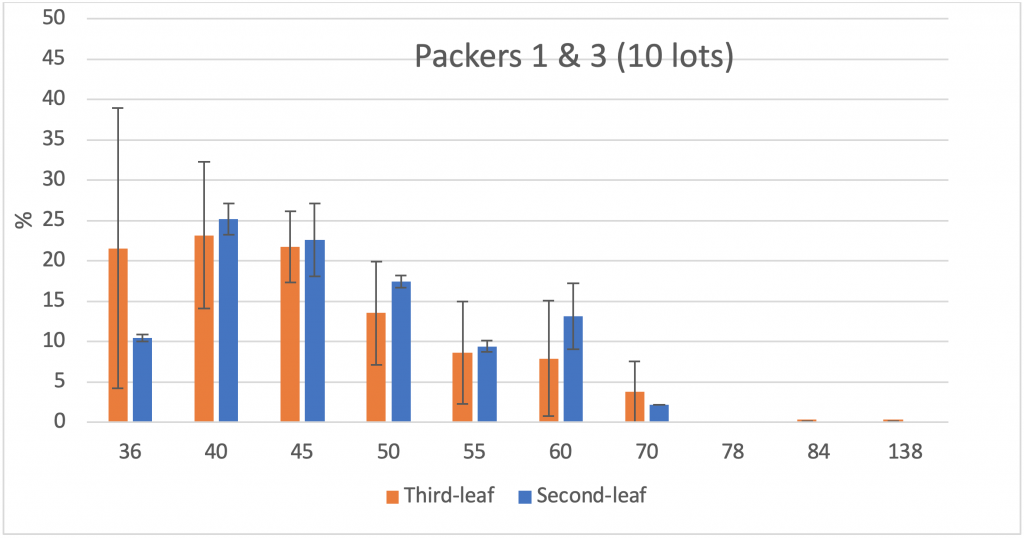

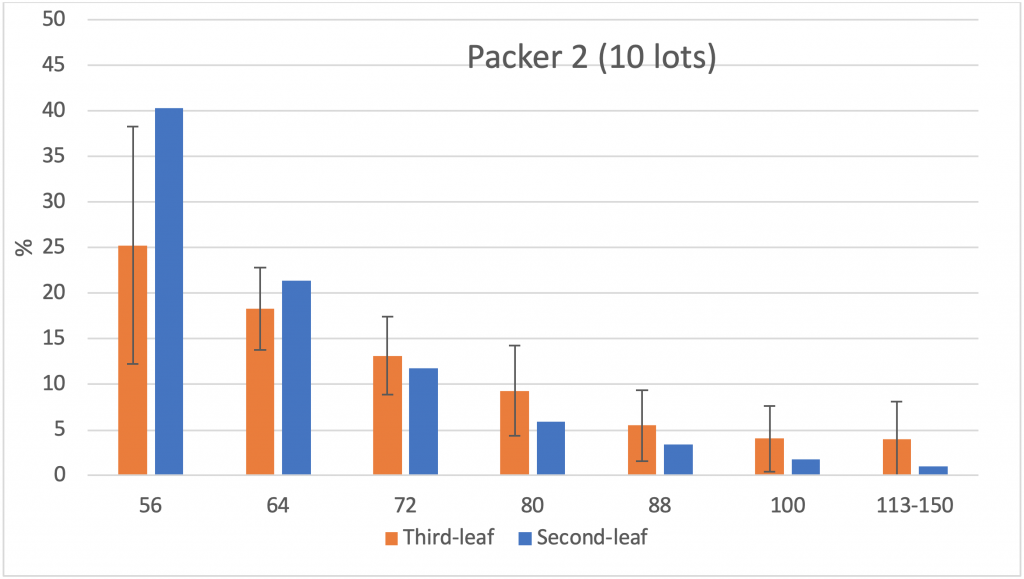

Average packout from third-year crop trees ranged from 63% to 94% and averaged 78%, denoting an average of 22% culled fruit. Fruit packout from second-year crop trees averaged 86%, with 14% of fruit culled (Figure 2). As expected in this variety (Hanrahan, 2020, View the size distribution article), fruit size was large and medium in both groups. Box size distribution is shown in figures 3 and 4.

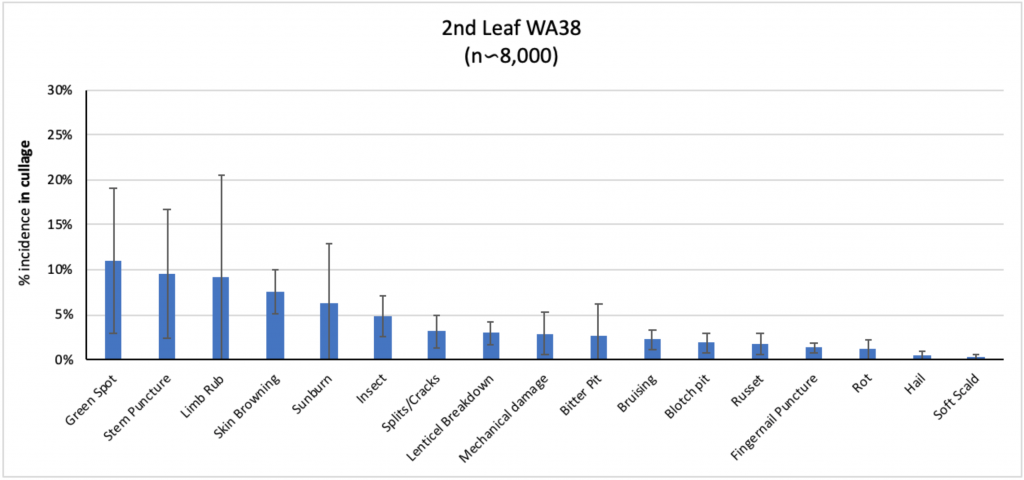

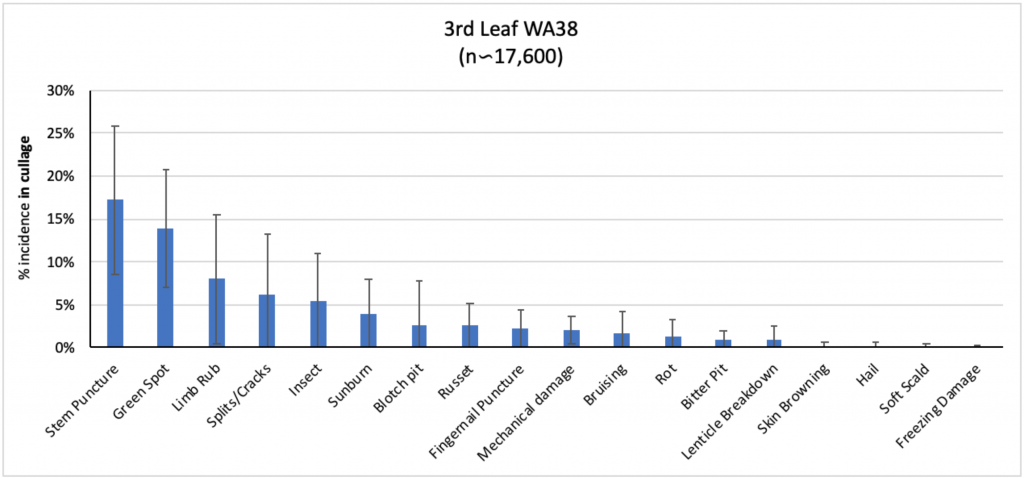

When pooling the cull types from 2nd and 3rd leaf trees, stem punctures (13.4% in culls, 2.5% in total fruit volume), Green Spot (12.4% in culls, 2.2% in total fruit processed volume), and limb rub (8.6% in culls, 1.5% in total fruit volume) were the top three. Mechanical-type damages (stem puncture, limb rub, fingernail punctures, mechanical damage) cumulatively accounted for 26.2% in culls and 4.8% in total fruit volume (in average 2nd and 3rd leaf-trees). In third-leaf trees, splits/cracks were the fourth biggest defect on culls with 6.1% (=1.3% in total fruit volume). In second-leaf trees, this place was for skin browning with 7.6% in culls (=1.0% in total fruit volume). Detailed information is provided in Figures 5 and 6, and Tables 1 and 2. It is important to mention that there was a significant difference between lots (represented by standard deviation lines on each column in Figures 5 and 6) and around 30% of the fruit in culls was clean but lacking red color in some cases (Figure 7), and that our assessment did not include the evaluation of defects on fruit that was left in the orchard and did not reach the packinghouse.

Table 1. Incidence (average percentage ± standard deviation) of defects found in cullage. Second leaf trees. January 2020.

| Defect | Incidence in Cullage (%) |

Incidence in total processed fruit volume (%) |

| Green Spot | 11.0 ± 8.1 | 1.4 |

| Stem Puncture | 9.6 ± 7.1 | 1.3 |

| Limb Rub | 9.1 ± 11.3 | 1.2 |

| Skin Browning | 7.6 ± 2.5 | 1.0 |

| Sunburn | 6.2 ± 6.7 | 0.8 |

| Insect | 4.9 ± 2.2 | 0.6 |

| Splits/Cracks | 3.2 ± 1.8 | 0.4 |

| Lenticel Breakdown | 3.0 ± 1.3 | 0.4 |

| Mechanical DAmage | 2.9 ± 2.3 | 0.4 |

| Bitter Pit | 2.7 ± 3.4 | 0.3 |

| Bruising | 2.2 ± 1.1 | 0.3 |

| Blotch Pit | 1.9 ± 1.1 | 0.2 |

| Russet | 1.7 ± 1.2 | 0.2 |

| Fingernail Puncture | 1.3 ± 0.5 | 0.2 |

| Rot | 1.1 ± 1.1 | 0.1 |

| Hail | 0.4 ± 0.5 | 0.1 |

| Soft Scald | 0.3 ± 0.3 | 0.0 |

Table 2. Incidence (average percentage ± standard deviation) of defects found in cullage. Third leaf trees. December 2019.

| Defect | Incidence in Cullage (%) |

Incidence in total processed fruit volume (%) |

| Stem Puncture | 17.2 ± 8.7 | 3.8 |

| Green Spot | 13.9 ± 6.9 | 3.0 |

| Limb Rub | 8.0 ± 7.5 | 1.7 |

| Splits/Cracks | 6.1 ± 7.1 | 1.3 |

| Insect | 5.4 ± 5.5 | 1.2 |

| Sunburn | 4.0 ± 4.1 | 0.9 |

| Blotch Pit | 2.7 ± 5.2 | 0.6 |

| Russet | 2.6 ± 1.6 | 0.5 |

| Fingernail Puncture | 2.3 ± 2.1 | 0.6 |

| Mechanical Damage | 2.1 ± 1.6 | 0.5 |

| Bruising | 1.7 ± 2.5 | 0.4 |

| Rot | 1.4 ± 1.8 | 0.2 |

| Bitter Pit | 0.9 ± 1.1 | 0.3 |

| Lenticel Breakdown | 0.9 ± 1.7 | 0.2 |

| Skin Browning | 0.2 ± 0.3 | 0.1 |

| Hail | 0.2 ± 0.4 | 0.0 |

| Soft Scald | 0.1 ± 0.2 | 0.0 |

| Freezing Damage | 0.0 ± 0.1 | 0.0 |

Clipping stems to control stem punctures have already shown to be economically feasible (and beneficial) for this variety (Hanrahan, 2018, view the stem puncture article). More in field control is needed to mitigate defects like limb rub, fingernail punctures, and mechanical damage. Regarding the disorder called ‘Green Spot”, there are ongoing investigations by Washington State University to understand its origin and how to control it in the field.

Compared to other fresh pack varieties, which typically have packouts in the low 70%s, WA 38 performed very well in its first year. However, WSU and Proprietary Variety Management (PVM), the company commercializing WA 38, expect an average packout of 85%. It is highly probable that as modern optical sorters become more familiar with the fruit, discrimination will become more precise, thus increasing packouts can be expected in subsequent growing seasons.

Fruit samples to assess maturity showed an average mass across all packers and cull types of 287.6 ±21.0 g, flesh firmness of 16.9 ± 0.3 lbs, 15.5°Brix of soluble solids, Starch index (1-6) of 5.7 (Figure 8), IAD of 0.4, with no differences between second and third leaf tree lots of fruit.

Fruit greasiness was a transversal issue observed this season and managed according to recommendations from different coatings providers. This is a phenomena caused by environmental growing conditions and advanced fruit maturity, particularly in susceptible cultivars. Therefore, in order to minimize this defect in the future, proper adjustments to harvest maturity need to be taken into consideration.

Contact

Carolina Torres

Carolina Torres

Postharvest Systems Endowed Chair

WSU-TFREC, Wenatchee

ctorres@wsu.edu

treefruit.wsu.edu articles may only be republished with prior author permission © Washington State University. Republished articles with permission must include: “Originally published by Washington State Tree Fruit Extension at treefruit.wsu.edu” along with author(s) name, and a link to the original article.